Speed limit signs must comply with strict MUTCD standards to ensure safety and legal enforceability. These rules apply to all roadways open to public travel and help maintain consistency nationwide. Non-compliance can lead to penalties, including loss of federal funding and increased liability.

Key highlights:

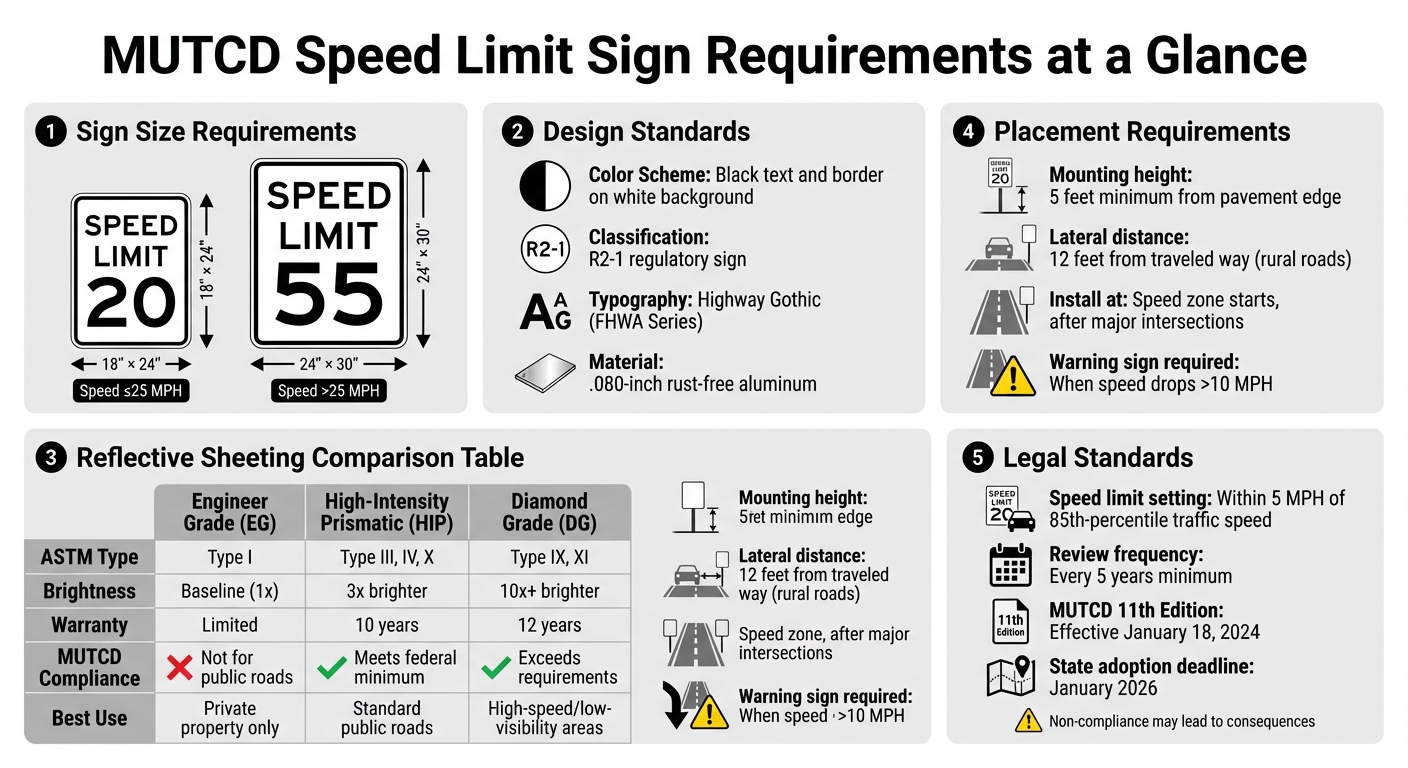

- Design: Black text and borders on a white background are mandatory. Sizes vary by speed limits - 18"x24" for 25 MPH or lower, 24"x30" for higher speeds.

- Materials: Signs must use .080-inch rust-free aluminum and High-Intensity Prismatic (HIP) reflective sheeting (minimum standard) for visibility.

- Placement: Install signs at speed zone starts, after intersections, and maintain 5 feet height from pavement edge. Use “Reduced Speed Limit Ahead” signs for drops over 10 MPH.

- Legal Standards: Speed limits should be within 5 MPH of the 85th-percentile traffic speed and reviewed every 5 years.

With the MUTCD 11th Edition effective January 2024, states must fully adopt updates by January 2026. Following these guidelines ensures safer roads and minimizes legal risks.

MUTCD 11th Edition Launch Video

MUTCD Standards for Speed Limit Signs

MUTCD Speed Limit Sign Requirements Comparison Chart

Required Sign Features

Speed limit signs, classified as R2-1, must adhere to specific standards to ensure legal compliance and easy recognition by drivers. The black text and border on a white background color scheme is mandatory across all jurisdictions. This uniformity helps drivers quickly identify regulatory speed limits, no matter where they are.

The size of the signs depends on the speed limit of the road. For roads with speeds 25 MPH or lower, signs must measure 18 inches wide by 24 inches tall. For roads with speeds above 25 MPH, the required dimensions increase to 24 inches wide by 30 inches tall. These measurements are designed to ensure drivers can see the signs from a safe distance.

Material requirements are equally important. Speed limit signs must be made from .080-inch thick rust-free aluminum, ensuring durability in outdoor environments. Reflectivity is another critical factor. Signs must feature High-Intensity Prismatic (HIP) sheeting as the minimum standard for roads open to public traffic. While Engineer Grade (EG) prismatic material is more affordable, it does not meet federal standards for state or federal roads.

| Reflective Sheeting Type | Brightness vs. Engineer Grade | ASTM Type | Warranty | MUTCD Compliance |

|---|---|---|---|---|

| Engineer Grade (EG) | Baseline | Type I | Limited | Not for public roads |

| High-Intensity Prismatic (HIP) | 3x brighter | Type III, IV, X | 10 years | Meets federal minimum |

| Diamond Grade (DG) / Ultra Prismatic | 10x+ brighter | Type IX or XI | 12 years | Exceeds requirements |

HIP sheeting is three times brighter than Engineer Grade and offers a 10-year warranty, while Diamond Grade is over 10 times brighter and comes with a 12-year warranty. Non-reflective signs can compromise visibility, especially in low-light conditions. These material standards not only improve clarity for drivers but also safeguard jurisdictions from legal challenges.

Legal and Safety Implications of Compliance

Meeting MUTCD standards is critical for both legal enforceability and road safety. Non-compliant signs can lead to serious issues, including the loss of federal funding and challenges in enforcing traffic citations. If signs fail to meet reflectivity or sizing requirements, they can increase liability risks, especially in cases where drivers claim they could not see or understand the speed limits.

The MUTCD mandates that speed limits be set within 5 mph of the 85th-percentile speed of free-flowing traffic. This ensures that speed limits align with actual driving patterns rather than arbitrary numbers. When speed limits deviate from this standard, enforcement becomes more difficult and may face legal challenges.

Additionally, non-statutory speed limits must be reviewed at least every 5 years, particularly if there have been significant changes in road conditions or surrounding land use. This periodic review ensures that speed limits remain relevant and enforceable. With the MUTCD 11th Edition becoming effective on January 18, 2024, states have until January 2026 to fully adopt the updated standards.

Proper placement of speed limit signs is another essential aspect of compliance. Signs must be installed at regular intervals, particularly at the start of new speed zones and after major intersections. To avoid confusing drivers, no more than three speed limits should appear on a single sign assembly.

Design and Material Requirements

Reflectivity and Durability Standards

Reflective sheeting plays a critical role in ensuring road signs remain visible at night. Products like 3M™ HIP sheeting meet federal visibility standards and come with a 10-year warranty. For enhanced visibility, Diamond Grade (DG) or Ultra Prismatic sheeting provides the highest reflectivity available. These advanced options, often required for federal highways or high-speed corridors in some states, include a 12-year warranty.

To maintain the reflective properties, it's essential to use translucent inks, vinyl, or films. Adding a protective overlay, such as 3M™ POF, can further extend the lifespan of the sign and shield it from UV fading.

Now, let’s look at the construction materials that ensure these standards are upheld.

Aluminum Construction Specifications

Speed limit signs are typically made from .080-inch thick, rust-free aluminum. This material balances durability with lightweight properties, making installation easier while withstanding wind loads. Thinner materials might warp over time, which could compromise both the sign’s appearance and its compliance with regulations.

Standard signs come with pre-punched 3/8-inch mounting holes at the top and bottom center, allowing for easy attachment to U-channel posts, square posts, or decorative round posts. The back of the sign can be finished in mill-finish aluminum, satin black powder coat, or custom colors to match the surrounding environment - all without affecting the compliance of the front-facing design.

With these sturdy materials in place, it’s possible to introduce custom elements without sacrificing regulatory compliance.

Adding Custom Elements While Maintaining Compliance

For public roadways, any extra information, such as "Photo Enforced" or "Fines Higher", must be displayed on separate plaques mounted below the primary sign, rather than on the sign face itself. However, on private properties like gated communities or parking lots, MUTCD standards are more flexible. Smaller signs, such as 12 inches by 18 inches, are allowed, along with broader customization options.

When creating custom speed limit signs, the speed must be displayed in 5 MPH increments on a vertical rectangular sign with a black legend and border on a white retroreflective background. If corporate logos or branding are included, they should be placed on a separate plaque below the R2-1 speed limit sign to ensure the regulatory message remains unobstructed.

sbb-itb-5d58da3

Placement and Installation Guidelines

Adhering to precise design and material standards is just the beginning. Correct placement and installation play a critical role in ensuring MUTCD compliance.

Mounting Height and Placement Requirements

For rural roads without shoulders, speed limit signs should be mounted 12 feet laterally from the traveled way, with the bottom edge positioned at least 5 feet above the pavement edge.

These signs need to be installed at every location where the speed limit changes. After major intersections, additional signs should be placed to remind drivers of the current speed limit. If the speed limit drops by more than 10 mph, a "Reduced Speed Limit Ahead" (W3-5) warning sign must be installed before the change.

In areas where curves or obstructions could block visibility, a second identical sign should be placed on the left-hand side of the roadway. To make signs more noticeable, consider adding retroreflective strips to the signposts.

Once the placement is determined, the right installation hardware is essential for durability and compliance.

Installation Methods and Hardware

Effective installation combines proper hardware with the placement standards to ensure signs remain secure and functional over time.

Speed limit signs come with pre-punched 3/8-inch mounting holes at the top and bottom center, making them easy to attach to U-channel, square, or round posts. Standard 24-inch by 30-inch signs typically require just one post, but larger assemblies may need multiple posts for added stability.

For permanent installations, using anti-theft mounting hardware can help deter tampering. In temporary or movable setups, such as construction zones, cast-iron bases weighing 20 to 35 pounds are a practical choice. These bases are priced between $129.95 and $139.95, while portable A-frame sign holders range from $124.95 to $163.95. Both options are ideal for areas where signs need to be relocated frequently.

TrafficSafetyHQ Speed Limit Sign Solutions

TrafficSafetyHQ produces speed limit signs that meet federal standards for use on public roads, private properties, and commercial facilities. Built with .080-inch rust-free aluminum and 3M or Avery reflective sheeting, these signs are designed for long-lasting durability and adhere to full MUTCD and ASTM D4956 compliance standards. With a focus on reliability and precision, these signs are crafted to ensure both safety and regulatory accuracy.

Product Features and Specifications

Our speed limit signs are designed with black text and borders on a white background, meeting the R2-1 regulatory standards. Customers can choose between two reflective sheeting options:

- High Intensity Prismatic (HIP): Offers a 10-year outdoor warranty, ideal for most road environments.

- Diamond Grade (DG): Provides a 12-year warranty, specifically engineered for high-speed roads and areas with low visibility.

Standard sizes include:

- 18 inches by 24 inches for speed limits of 25 mph or less.

- 24 inches by 30 inches for speeds over 25 mph.

These specifications ensure compliance while allowing flexibility for unique use cases.

Custom Sign Options

For private roadways, campuses, or parking lots, TrafficSafetyHQ offers customization options. Property managers and businesses can add logos, artwork, or custom text to MUTCD-compliant signs. Available sizes include:

- 12 inches by 18 inches: Priced at $48.95.

- 18 inches by 24 inches: Priced at $64.95.

All custom signs use Highway Gothic (FHWA Series) typography to maintain compliance. Customers can request a proof to confirm design details before production.

Bulk Ordering and Procurement Options

TrafficSafetyHQ simplifies large-scale projects with bulk ordering options. Volume discounts bring the cost of standard speed limit signs down to $28.34 per unit. Government and commercial clients benefit from Net-30 payment terms, making procurement straightforward.

Shipping is quick and reliable:

- Stock signs: Ship within 24 hours.

- Custom orders: Ship within 2 to 5 days.

For assistance, our support team is available via phone, email, or online chat to provide quotes and technical guidance. Verified buyers consistently rate our signs 5/5, highlighting their precision and excellent quality.

Conclusion

Effective compliance with MUTCD standards boils down to three key factors: materials, design, and proper installation. When creating speed limit signs, these elements play a critical role in ensuring both functionality and safety. Signs should be crafted using .080-inch thick aluminum paired with high-quality reflective sheeting like High Intensity Prismatic (HIP) or Diamond Grade (DG). This combination ensures durability against harsh weather and maintains visibility at night. Non-reflective signs, on the other hand, significantly reduce visibility in low-light conditions.

Speed limit signs must adhere to specific design guidelines: a white background with black text and borders, speed increments in multiples of 5 mph, and compliance with size standards . Placement is equally important. Proper mounting height, lateral distance, and strategic positioning at speed transition zones are critical to ensuring drivers can see and respond to these signs effectively.

Regularly reviewing and updating speed limits is crucial as road conditions evolve. Maintenance is equally vital - whether through visual nighttime inspections or retroreflectivity measurements - to ensure that signs remain compliant and effective throughout their lifespan .

With the MUTCD 11th Edition taking effect on January 18, 2024, and requiring state adoption by January 2026, compliance becomes a pressing priority. Beyond meeting legal obligations, following these standards is a proactive step toward improving road safety for everyone.

For those looking for reliable and compliant solutions, TrafficSafetyHQ provides expertly designed speed limit signage that aligns with these regulations, helping to make roads safer for all motorists.

FAQs

What happens if speed limit signs don’t comply with MUTCD standards?

If speed limit signs don’t comply with MUTCD standards, they might lose their legal enforceability. This could cause serious problems, such as greater liability for the agencies managing the signs and possible legal challenges. Beyond that, non-compliant signs can jeopardize public safety and confuse drivers, raising the likelihood of accidents and other road hazards.

How often should speed limits be reviewed to stay compliant with MUTCD guidelines?

According to the Manual on Uniform Traffic Control Devices (MUTCD) guidelines, speed limits need to be reassessed at least every five years. These routine reviews help ensure that limits align with current road conditions, evolving traffic patterns, and updated safety standards. Keeping speed limits up-to-date not only promotes safer and smoother traffic flow but also minimizes potential liability issues for authorities.

What materials are needed for speed limit signs to comply with MUTCD standards?

Speed limit signs that comply with MUTCD standards are crafted using .080-inch aluminum, chosen for its durability. They are then coated with retroreflective sheeting approved by the MUTCD to ensure visibility. Popular choices for this sheeting include high-intensity prismatic and diamond-grade films, which perform well under different lighting and weather conditions.

This combination of materials not only boosts safety but also ensures the signs meet federal requirements for extended outdoor use.