Traffic signs are crucial for nighttime driving safety, thanks to retroreflectivity - a property that reflects light back to its source, making signs visible in low-light conditions. Retroreflectivity degrades over time due to weather, UV exposure, and wear, which is why federal standards, like those in the Manual on Uniform Traffic Control Devices (MUTCD), require maintaining minimum brightness levels for regulatory, warning, and guide signs.

Key Points:

- Why It Matters: Nighttime accounts for 55% of fatal traffic accidents, even though only 25% of travel occurs after dark. Retroreflective signs help reduce risks, especially for older drivers who need more light to see clearly.

- How It Works: Retroreflective sheeting, made with glass beads or prismatic materials, redirects light from headlights back to drivers, ensuring visibility.

- MUTCD Standards: Agencies must assess and maintain retroreflectivity using approved methods like nighttime visual inspections, retroreflectometers, or scheduled replacements.

- Material Choices: High-performance materials like prismatic sheeting (Types III–IX) last longer and improve visibility, though they cost more upfront.

To stay compliant, agencies need a clear inventory system, proper maintenance methods, and durable materials. This ensures safer roads and reduces liability while meeting federal guidelines.

Traffic Sign Retroreflectivity – Webinar Series Part 1

MUTCD Retroreflectivity Requirements

The Manual on Uniform Traffic Control Devices (MUTCD) outlines strict guidelines to ensure traffic signs are visible on all public roads, prioritizing driver safety and consistency.

MUTCD Sections 2A.21 and 2A.22 Overview

Section 2A.21 sets the baseline for visibility, requiring that all traffic signs be either retroreflective or illuminated. This ensures they maintain their shape and color under both daylight and nighttime conditions.

Section 2A.22 focuses on maintenance, requiring public agencies to adopt a formal assessment or management approach to keep sign retroreflectivity at or above the specified minimum levels. According to the MUTCD:

"Public agencies or officials having jurisdiction shall use an assessment or management method that is designed to maintain sign retroreflectivity at or above the minimum levels."

This means agencies must employ an approved method to evaluate retroreflectivity. If a sign no longer meets the minimum standards, it must be replaced. However, as long as the agency is actively using an approved method, they remain compliant - even if some signs temporarily fall below the required levels. Once a sign is identified as failing to meet the minimum retroreflectivity, it is considered to have reached the end of its service life and must be replaced.

Certain signs are exempt from these requirements, including parking (R7/R8), pedestrian-related (R9), acknowledgment signs, and those with blue or brown backgrounds.

These rules provide the foundation for the specific assessment methods discussed later.

Minimum Retroreflectivity Levels by Sign Type

To meet the MUTCD’s safety standards, traffic signs must adhere to specific retroreflectivity values. These levels are based on research aimed at accommodating older drivers, who may have reduced nighttime visibility. Retroreflectivity levels vary depending on the sign's color and contrast, as these factors influence nighttime visibility.

Retroreflectivity is measured as the coefficient of retroreflectance (RA) in candelas per lux per square meter (cd/lx/m²). Here are the minimum values for common sign types:

| Sign Color | Sheeting Type | Minimum RA (cd/lx/m²) |

|---|---|---|

| White on Red (STOP, YIELD) | All Types | White: 35; Red: 7 |

| Black on Yellow (Warning) | Beaded (Types I, II, III) | 75 |

| Black on Yellow (Warning) | Prismatic (Types III, IV, VII, VIII, IX, X) | 50 |

| Black on Orange (Work Zone) | Beaded | 75 |

| Black on Orange (Work Zone) | Prismatic | 50 |

| White on Green (Guide Signs) | Beaded (Types I, II) | White: 7; Green: 7 |

| White on Green (Guide Signs) | Prismatic (Types III and above) | White: 250; Green: 25 |

Fluorescent yellow and orange signs must meet the same retroreflectivity levels as their standard counterparts.

Prismatic sheeting (Types III–XI) is often preferred because it offers better performance and lasts longer. While its upfront cost is higher, it can reduce replacement expenses over time. For overhead guide signs, only prismatic sheeting (Type III or higher) is permitted for white legends, as beaded sheeting does not meet the required performance standards.

FHWA-Approved Assessment Methods

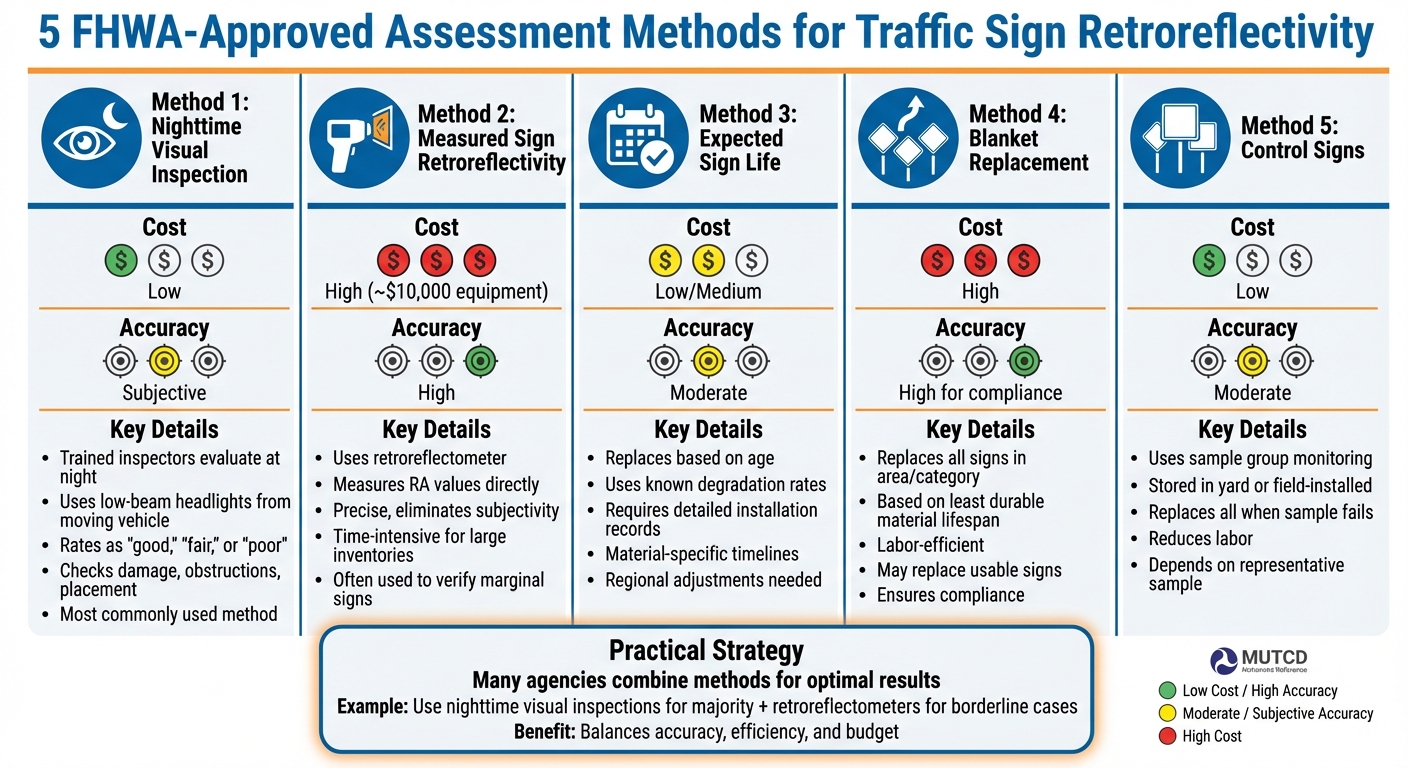

FHWA Traffic Sign Assessment Methods Comparison Chart

The Federal Highway Administration (FHWA) has outlined practical methods to help agencies maintain sign retroreflectivity, building on the requirements set by the Manual on Uniform Traffic Control Devices (MUTCD). These methods offer tools to ensure signs remain visible and meet safety standards.

The 5 Assessment Methods

Nighttime Visual Inspection is the most commonly used method due to its low upfront cost. Trained inspectors evaluate signs at night from a moving vehicle using low-beam headlights, rating visibility as "good", "fair", or "poor." This method not only checks retroreflectivity but also considers physical damage, obstructions, and placement. However, it’s subjective and relies on qualitative assessments rather than precise data.

Measured Sign Retroreflectivity involves using a handheld retroreflectometer, which costs about $10,000, to measure retroreflectivity (RA) values directly against MUTCD standards. This method is precise and eliminates subjectivity but can be very time-intensive for large inventories. Agencies often use it to confirm marginal signs flagged during visual inspections rather than testing every sign.

Expected Sign Life replaces signs based on their age and known degradation rates for specific sheeting materials in a given region. This method requires agencies to maintain detailed records of installation dates and materials to ensure accuracy.

Blanket Replacement replaces all signs in a specific area or category at regular intervals, based on the lifespan of the least durable material. While efficient in terms of labor and ensures compliance, this approach can result in replacing signs that still have remaining usability.

Control Signs use a sample group of signs, either stored in a maintenance yard or installed in the field, to monitor overall retroreflectivity. When the control sample falls below acceptable levels, all similar signs are replaced. This method reduces labor but depends heavily on the representativeness of the sample.

Comparing Assessment Methods

| Assessment Method | Cost | Accuracy | Practical Considerations |

|---|---|---|---|

| Nighttime Visual Inspection | Low | Subjective | Requires night work and evaluates overall sign condition, including damage and placement. |

| Measured Retroreflectivity | High | High | Provides precise measurements but is time-consuming for large inventories. |

| Expected Sign Life | Low/Medium | Moderate | Relies on accurate records of installation dates and sheeting materials. |

| Blanket Replacement | High | High (for compliance) | Labor-efficient but may replace signs prematurely. |

| Control Signs | Low | Moderate | Less labor-intensive but hinges on having a reliable, representative sample. |

Practical Strategies for Agencies

Many agencies combine methods to balance accuracy and efficiency. For example, they might use nighttime visual inspections to evaluate the majority of their inventory and then deploy retroreflectometers to verify borderline cases. This hybrid approach helps stretch maintenance budgets while ensuring compliance and providing documentation to protect against liability claims.

To ensure consistent visual inspections, agencies should train inspectors with sample signs that meet minimum retroreflectivity levels and regularly check that inspection vehicles are properly equipped. Vehicles should have clean windshields and correctly aimed, new headlights to ensure reliable results.

sbb-itb-5d58da3

How to Maintain Compliance

Sign Inventory and Replacement Planning

Staying compliant starts with a clear understanding of your sign inventory and a well-thought-out plan for replacements. Many agencies rely on computerized sign management systems (SMS) to keep track of crucial details like installation dates, materials, and orientations. These systems can alert you when retroreflectivity levels are about to fall below the required minimums, even generating work orders automatically. For field crews who may not have immediate access to digital systems, physical labeling - using coded or color-coded systems - offers a quick and reliable way to identify a sign's age and condition.

When it comes to managing sign replacements, agencies have options to fit their specific needs. The Expected Sign Life method uses manufacturer warranties as a guideline: 7 years for ASTM Types I and II, 10 years for Types III and IV, and 12 years for Types VII, VIII, IX, and X. Interestingly, research from Indiana and Michigan shows that some materials, like Type III beaded high-intensity sheeting, can last up to 15 years, surpassing warranty expectations. Adjustments to these timelines may be necessary based on local conditions like UV exposure or how signs are positioned. Alternatively, some agencies, like the City of Glendale, Arizona, use a blanket replacement strategy. This method involves replacing all signs in a specific area at the same time, simplifying compliance efforts and reducing the need to track individual sign ages.

Once a monitoring and replacement system is in place, selecting high-quality materials becomes the next step in ensuring compliance.

Selecting Durable Materials and Sheeting

Effective inventory management is only part of the equation - choosing the right materials is just as important for maintaining compliance over the long haul. Aluminum substrates are widely used because they’re durable, lightweight, and recyclable. For outdoor signs, .080" aluminum is the go-to thickness, offering the strength needed for outdoor conditions while keeping installation manageable.

Reflective sheeting is another critical factor in sign performance and durability. Engineering Grade (Type I) sheeting, for example, is no longer suitable for warning signs or white legends on green guide signs because it doesn’t meet current retroreflectivity standards. High Intensity Prismatic (Type IV) sheeting is a better option, offering clear visibility from about 1,000 feet and typically backed by a 10-year warranty. For even greater visibility, Diamond Grade (Type IX) sheeting is up to ten times brighter than Engineering Grade, provides visibility up to 1,500 feet, and comes with a 12-year warranty.

Companies like TrafficSafetyHQ produce signs using .080" aluminum paired with 3M™ High Intensity Prismatic and Diamond Grade reflective sheeting. These products meet both MUTCD and ASTM D4956 standards and come with a 10-year durability guarantee. While higher-grade sheeting costs more upfront, its longer service life - often 12 to 15 years - can result in significant savings over time, especially for agencies managing large inventories.

Conclusion

Retroreflectivity standards play a crucial role in ensuring safety during nighttime driving. Although only about 25% of travel happens after dark, nearly 50% of traffic fatalities occur during these hours. Retroreflective signs help restore the visual guidance that darkness obscures, aiding drivers in navigating safely and reducing crash risks. This is especially important for older drivers, who often face greater challenges with vision in low-light conditions.

Maintaining retroreflectivity isn't just about meeting safety goals - it’s also about adhering to regulations. Compliance with MUTCD standards not only ensures safer roads but also shields agencies from liability and the risk of losing Federal-aid funding. The MUTCD emphasizes this clearly:

"Public agencies or officials having jurisdiction shall use an assessment or management method that is designed to maintain sign retroreflectivity at or above the minimum levels".

To comply, agencies must adopt one of the five FHWA-approved methods for assessing retroreflectivity: visual nighttime inspections, measured retroreflectivity, expected sign life, blanket replacement, or control signs. Consistent implementation of any of these methods keeps agencies in compliance, even if some signs occasionally fall below the required levels. Keeping detailed records of maintenance activities not only aids with budgeting but also provides legal protection.

The materials used in signs directly affect their performance and longevity. For instance, Type I Engineering Grade sheeting no longer meets the standards for warning signs due to its inability to maintain retroreflectivity over time. In contrast, higher-performance materials like Type IV High Intensity Prismatic or Type IX Diamond Grade sheeting, though more expensive upfront, retain retroreflectivity longer and are more cost-effective in the long run.

The combination of proper compliance measures and high-quality materials ensures safer roads. Companies such as TrafficSafetyHQ manufacture signs using .080" aluminum and pair them with 3M™ High Intensity Prismatic and Diamond Grade reflective sheeting. These signs meet MUTCD and ASTM D4956 standards and come with a 10-year durability guarantee. By using durable materials and adhering to MUTCD guidelines, TrafficSafetyHQ helps extend the life of signs, enhance road safety, and reduce long-term costs. Quality materials and careful compliance work hand in hand to create a safer driving environment.

FAQs

What makes retroreflectivity essential for traffic signs?

Retroreflectivity plays a key role in road safety by reflecting vehicle headlights back toward drivers. This makes traffic signs easier to see and read, especially in low-light conditions or at night. Clear visibility of signs helps drivers navigate more safely and lowers the chances of accidents.

Adhering to retroreflectivity standards not only ensures compliance with federal safety regulations but also enhances overall roadway safety. Highly reflective signs are especially crucial for older drivers or individuals with vision impairments, as they depend on clear, visible signage to make quick and informed decisions while driving.

How do agencies comply with MUTCD retroreflectivity standards for traffic signs?

Agencies maintain compliance with MUTCD retroreflectivity standards by establishing routine programs to evaluate and manage the visibility of traffic signs. This process often includes nighttime visual inspections and the use of specialized, calibrated tools to measure retroreflectivity levels. Typically, these inspections are carried out every 1–2 years to pinpoint signs that no longer meet the minimum retroreflectivity values outlined in the MUTCD guidelines.

If a sign falls short of the required standards, it is quickly replaced to ensure both safety and compliance. These efforts play a crucial role in keeping traffic signs highly visible and functional, particularly in low-light conditions, which directly contributes to safer roadways.

What are the advantages of using high-performance prismatic sheeting for traffic signs?

High-performance prismatic sheeting brings several advantages to traffic signs. First, it delivers outstanding retroreflectivity, making signs easy to see even in nighttime or low-light conditions. This heightened visibility helps drivers respond more quickly, contributing to safer roads.

On top of that, these materials are built to last. They’re tough and resistant to weather, designed to endure harsh outdoor conditions without losing their reflective quality. Plus, they comply with MUTCD and ASTM standards, ensuring they meet federal requirements for safety and visibility.