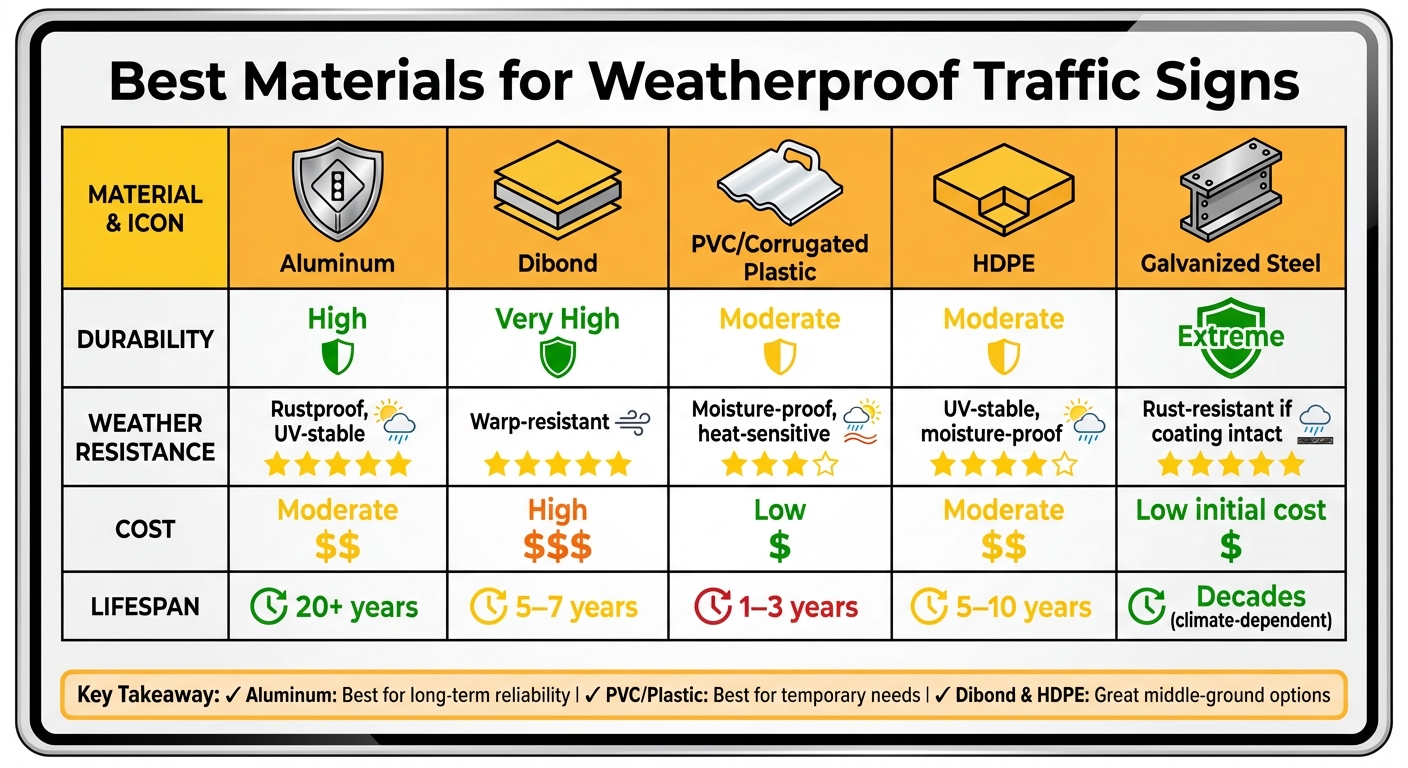

Traffic signs must endure harsh weather while remaining visible and functional. The best materials balance durability, weather resistance, and cost-effectiveness. Here's a quick breakdown:

- Aluminum: Long-lasting (20+ years), rustproof, UV-stable, and low maintenance. Best for permanent signs.

- Dibond: Lightweight aluminum composite, resists warping, lasts 5–7 years. Ideal for large-format signs.

- PVC/Corrugated Plastic: Affordable but short-lived (1–3 years). Suitable for temporary signs.

- HDPE: Impact-resistant and moisture-proof, lasts 5–10 years. Good for semi-permanent signs.

- Galvanized Steel: Strong and impact-resistant but prone to rust once the zinc coating wears off. Lifespan varies with climate.

Quick Comparison

| Material | Durability | Weather Resistance | Cost | Lifespan |

|---|---|---|---|---|

| Aluminum | High | Rustproof, UV-stable | Moderate | 20+ years |

| Dibond | Very High | Warp-resistant | High | 5–7 years |

| PVC/Plastic | Moderate | Moisture-proof, heat-sensitive | Low | 1–3 years |

| HDPE | Moderate | UV-stable, moisture-proof | Moderate | 5–10 years |

| Galvanized Steel | Extreme | Rust-resistant (if intact) | Low | Decades (varies) |

Takeaway: Aluminum is the top choice for long-term reliability, while PVC and plastic are best for short-term needs. Dibond and HDPE are great middle-ground options based on specific project requirements.

Traffic Sign Materials Comparison: Durability, Weather Resistance, Cost and Lifespan

What Materials Are Used To Make Traffic Signs? - CountyOffice.org

1. Aluminum

Aluminum is a go-to material for professional traffic signage, meeting the 5052-H38 alloy standards required by nationwide government regulations. One of its standout features is the natural oxide layer that forms when exposed to oxygen, protecting it from rust. This self-protective trait eliminates the need for the extensive corrosion treatments that steel requires, making aluminum a durable and reliable option.

Durability

Aluminum’s impressive strength-to-weight ratio makes it ideal for outdoor signs. Common thicknesses range from 0.063 to 0.125 inches, ensuring the material is rigid enough to handle strong winds without bending or deforming. At the same time, its lightweight nature simplifies installation and reduces stress on supporting structures.

"The inherent corrosion resistance of aluminum makes it a reliable and long-lasting material for traffic signs, capable of withstanding the rigors of outdoor exposure without succumbing to rust." - Barry K. Brown, Sign Industry Expert

TrafficSafetyHQ uses .080" aluminum combined with 3M™ reflective sheeting, ensuring compliance with MUTCD standards. This pairing not only guarantees structural integrity but also provides a substrate that often outlasts the reflective film itself.

Weather Resistance

Aluminum excels in extreme weather conditions. It doesn’t absorb moisture, so it won’t warp, split, or rot - even after prolonged exposure to rain or snow. In coastal areas, where saltwater accelerates corrosion, anodized or powder-coated aluminum offers an extra layer of protection. Unlike plastic, which can become brittle and fade under UV exposure, aluminum retains its strength and appearance without cracking or discoloring.

Cost

Although aluminum costs more upfront than PVC, its long lifespan makes it a cost-effective choice. While plastic signs may need replacing every 1–2 years, aluminum signs typically last 7 to 10 years, with premium options lasting over 12 years.

Lifespan

The lifespan of aluminum signs depends on the type of reflective sheeting used:

- Engineer Grade: Around 7 years

- High-Intensity Prismatic (HIP): About 10 years

- Diamond Grade: Exceeds 12 years

The aluminum itself often outlasts the reflective film, requiring minimal upkeep - just an occasional cleaning with mild soap and water to maintain visibility. This durability cements aluminum’s status as a leading choice for weather-resistant traffic signage.

2. Dibond (Aluminum Composite)

Dibond is made by sandwiching a polyethylene core between two thin layers of aluminum. This design makes it about 50% lighter than solid aluminum while still maintaining its rigidity. Its lighter weight not only simplifies installation but also ensures it remains structurally sound.

Durability

The polyethylene core plays a crucial role in Dibond's durability, acting as a shock absorber. This feature allows it to handle impacts better than solid aluminum, which tends to bend under similar conditions. However, Dibond’s outdoor lifespan is shorter - typically 5–7 years, compared to solid aluminum’s 20+ years. Despite this, its ability to withstand impacts makes it a reliable choice for many applications, especially where weather resistance is important.

Weather Resistance

Dibond holds its shape even in extreme weather, resisting warping and oil-canning caused by direct sunlight or temperature changes. The outer aluminum layers protect the polyethylene core from UV damage and moisture, while the rust-proof surface makes it ideal for areas with high humidity or near coastal environments. Unlike PVC, which often warps in heat and lasts only 1–3 years outdoors, Dibond maintains its stability throughout its lifespan.

Cost

The advanced construction of Dibond does come with a higher initial cost compared to solid aluminum or PVC. However, its durability and low maintenance needs - cleaning usually requires just soap and water - can offset the upfront expense in the long run. This makes it a practical choice for applications where flatness and appearance are critical.

Lifespan

For official traffic signage, solid aluminum is still the go-to material due to its ability to meet MUTCD standards and its multi-decade lifespan. Dibond, with its 5–7 year outdoor lifespan, is better suited for large-format displays or site signage where aesthetics and resistance to warping take precedence over the extended durability required for permanent street signs.

3. PVC (Polyvinyl Chloride) and Corrugated Plastic

PVC board (commonly sold under names like Sintra or Forex) and corrugated plastic (often referred to as Coroplast) are budget-friendly options for signage. Both materials are waterproof, making them suitable for damp or humid environments. However, these materials fall short in terms of durability and longevity when compared to aluminum-based alternatives. Let’s take a closer look at how they hold up under various conditions.

Durability

PVC board offers decent structural strength but struggles in high heat, where it tends to warp over time. This makes it less suitable for large, unsupported signs in hot climates. Corrugated plastic, on the other hand, has a lightweight, hollow design that bends easily in strong winds. Over time, it becomes brittle and degrades faster than most other materials.

Weather Resistance

Both PVC and corrugated plastic perform well in wet conditions. PVC resists water absorption and doesn’t delaminate, while corrugated plastic stays waterproof throughout its use. However, neither material can compete with aluminum in terms of UV resistance. Corrugated plastic is often used for temporary promotional signs but isn’t durable enough for long-term outdoor use. In areas prone to high winds, it’s a good idea to secure corrugated plastic with a rigid backing to prevent it from bending or blowing away.

Cost

Affordability is a key advantage of these materials. Corrugated plastic stands out for being particularly inexpensive, while PVC offers a low-cost alternative to metal signs. Their economical pricing makes them ideal for projects requiring frequent updates, such as seasonal campaigns or temporary installations.

Lifespan

When it comes to longevity, these materials fall far behind aluminum. PVC typically lasts 5–7 years in moderate climates but only 1–3 years in harsher conditions. Corrugated plastic has an even shorter lifespan, lasting just 1–2 years outdoors under normal conditions. According to BuildASign, their 4mm corrugated plastic signs generally last 12–18 months in most environments. Because of this, PVC and corrugated plastic are better suited for temporary uses like event signage, short-term construction detours, or directional signs, rather than permanent installations like street signage.

sbb-itb-5d58da3

4. HDPE (High-Density Polyethylene)

HDPE strikes a balance between affordability and durability, making it a solid alternative to both low-cost plastics and premium materials like aluminum. It's often used as a core material in composite panels or as standalone sign boards, especially in settings where impact resistance and low maintenance are key priorities.

Durability

HDPE is tough and built to last, offering performance on par with aluminum and Dibond, but with its own unique advantages. One standout feature is its ability to handle impacts without permanent damage. Unlike aluminum, which can dent on impact, HDPE disperses energy effectively. Its manufacturing process involves extrusion, which fuses color layers into a single, uniform structure. This makes it resistant to delamination, cracking, or chipping, even under environmental stress. On top of that, its surface is naturally resistant to scratches and graffiti, allowing for easy cleaning without harming the material underneath.

Weather Resistance

HDPE is designed to withstand outdoor conditions. Thanks to its UV-stabilized composition, it holds its color and resists becoming brittle even after long-term exposure to sunlight. The material is also moisture-resistant, meaning it won’t rot or corrode, making it ideal for use in humid or coastal areas. However, because its mechanical properties differ from traditional materials like aluminum, careful engineering calculations - guided by standards like ASCE 7-95 - are necessary to determine the correct thickness for handling wind loads.

Cost and Lifespan

When it comes to pricing, HDPE falls in the middle - more expensive than basic PVC but more affordable than solid aluminum. In outdoor environments, signs made with HDPE cores typically maintain their clarity and strength for 5–10 years. While this lifespan is shorter than aluminum, it far exceeds that of corrugated plastic, making HDPE a practical choice for semi-permanent installations. It’s particularly appealing for projects where longevity is important but decades of durability aren’t required. Plus, HDPE is easy to work with - CNC routing is straightforward and requires little finishing, which helps keep production costs manageable.

5. Galvanized Steel

Galvanized steel is known for its impressive strength, making it a reliable choice for signs that need to handle physical impacts or carry heavy loads. Its zinc coating forms a protective layer called zinc carbonate, which helps prevent rust for as long as 50 years with proper maintenance.

Durability

What sets galvanized steel apart is its high strength, but this comes with a trade-off: its heavier weight requires sturdier mounting hardware. The material's durability largely depends on the condition of its zinc coating. As long as the coating remains intact, the steel underneath is well-protected. However, once the coating wears away, the steel begins to corrode much faster than aluminum would under similar circumstances.

Weather Resistance

Galvanized steel performs well in dry or moderate climates, but it faces challenges in environments with consistent humidity levels above 60%, industrial pollution, or salty coastal air. These conditions can speed up the degradation of its protective zinc layer. While the zinc coating can tolerate high temperatures - up to 787°F - combining heat with humidity or pollution accelerates corrosion.

Cost and Lifespan

Initially, galvanized steel is more affordable than aluminum. However, its lifespan is heavily influenced by environmental factors. While it may seem cost-effective at first, the material corrodes more quickly than aluminum, especially in harsh or humid environments. Aluminum signs, on the other hand, can last over 20 years with minimal upkeep. In areas with challenging conditions, the need for more frequent replacements and maintenance can offset the initial savings, making aluminum a smarter long-term investment for permanent signage. This highlights the balance between upfront cost and long-term durability in choosing the right material.

Advantages and Disadvantages

Each material discussed comes with its own set of strengths and weaknesses, making them suitable for different installation needs. Let's break it down:

Aluminum is often considered the go-to option for permanent installations. It boasts a lifespan of over 20 years, requires little maintenance, and naturally resists rust. However, its moderate cost might deter those working within tighter budgets. Dibond, on the other hand, is over ten times stronger than standard aluminum, making it ideal for large-format displays where maintaining a flat surface is crucial. That said, its higher price tag limits its practicality for smaller, budget-conscious projects.

For more temporary signage, PVC and corrugated plastic are the most affordable choices. They work well for short-term use (1–3 years) but are prone to issues like heat warping and brittleness from UV exposure over time. HDPE offers a balanced option with decent vibration resistance and flexibility, though its lifespan can vary based on environmental factors. Meanwhile, galvanized steel delivers exceptional impact resistance and can last for decades in dry climates. However, once its zinc coating wears off, it becomes more vulnerable to corrosion, especially in humid or coastal areas.

Here's a quick comparison of these materials based on key factors:

| Material | Durability | Weather Resistance | Relative Cost | Lifespan |

|---|---|---|---|---|

| Aluminum | High | Excellent (Rustproof/UV Stable) | Moderate | 20+ Years |

| Dibond | Very High | Excellent (Warp-resistant) | High | 5–7 Years |

| PVC | Moderate | Good (Moisture-proof; Heat-sensitive) | Low | 1–3 Years |

| HDPE | Moderate | Good (Ductile/Vibration-resistant) | Moderate | Variable |

| Galvanized Steel | Extreme | Excellent (if coating intact) | Low (initial) | Decades (climate-dependent) |

Ultimately, the best material comes down to balancing your budget with the required lifespan and the environmental conditions. For short-term signage lasting under two years, corrugated plastic offers an affordable and weather-resistant solution.

Conclusion

Choosing the right material for weatherproof traffic signs boils down to aligning the material's performance with the specific demands of the application. Among the available options, aluminum stands out as the go-to choice for permanent installations. With a service life exceeding 20 years, it offers unmatched durability, requires minimal maintenance, and is completely rustproof.

For long-term reliability, .080" gauge solid aluminum paired with High Intensity Prismatic reflective sheeting hits the mark. This combination not only meets federal standards but also ensures compliance with MUTCD and DOT guidelines. TrafficSafetyHQ uses this exact specification, delivering signs that perform consistently for decades. While aluminum may have a higher upfront cost, its extended lifespan makes it a cost-effective solution over time by reducing annual replacement expenses.

For shorter-term needs, budget-friendly options like PVC or corrugated plastic are available. These materials are ideal for temporary signage, lasting between 1–3 years at a low cost. Meanwhile, Dibond offers a great solution for large-format signs in windy areas, thanks to its rigidity and warp resistance, with a service life of 5–7 years.

Local environmental conditions also play a critical role in material selection. For instance, pure aluminum is the best choice for coastal areas where salt air accelerates corrosion. In contrast, Dibond performs well in regions with high temperatures due to its ability to resist warping.

As Andrew Miller from SF Bay Signs puts it:

"Aluminum has earned its reputation as the go-to material for outdoor signs that need to last. This lightweight metal offers an exceptional combination of strength, weather resistance, and longevity".

FAQs

What should I look for when choosing materials for traffic signs in coastal areas?

When choosing materials for traffic signs in coastal regions, you need to consider the tough environmental conditions these areas present. The salty air speeds up corrosion, making high-grade aluminum a smart choice because it resists rust. Additionally, strong winds, high humidity, and saltwater spray demand materials that won’t warp, swell, or break down over time.

A great option is .080-inch aluminum combined with a protective coating and 3M™ reflective sheeting. This pairing keeps the sign rust-free, UV-resistant, and easy to see, even in intense sunlight. Using durable materials like these not only cuts down on maintenance but also extends the lifespan of the signs, ensuring they remain effective in coastal environments.

TrafficSafetyHQ provides federally compliant signs crafted with these premium materials, specifically designed to handle the challenges of coastal conditions while retaining their visibility and durability over time.

Is aluminum more cost-effective than other materials for weatherproof traffic signs?

Aluminum signs might seem pricier at first glance compared to plastic, but they pay off over time. Their strength, resistance to corrosion, and impressive 7-10 year lifespan mean they outlast plastic signs, which generally hold up for just 1-5 years.

Because they need to be replaced far less often, aluminum signs help cut down on maintenance and replacement expenses, making them a solid choice for durable, weather-resistant traffic signage.

Why is HDPE a good material for semi-permanent traffic signs?

HDPE, or high-density polyethylene, is an excellent material for semi-permanent traffic signs due to its long-lasting durability and resistance to weather conditions. Its UV-stabilized design ensures that colors remain vibrant and the material stays intact, even after extended exposure to sunlight.

What sets HDPE apart is its combination of being lightweight and strong, which simplifies installation without compromising on sturdiness. It’s also resistant to scratches, graffiti, and cracking, making it a low-maintenance choice. Cleaning is straightforward, and the material allows for precise cutting, ensuring sharp, professional lettering and graphics. These qualities make HDPE a practical and reliable option for outdoor traffic signage.